Trusting the Data: How AIs are Revolutionising UK Supply Chains

TalkTalk Business recently commissioned research into how UK logistics workers – frontline employees and IT leaders – view the future of supply chain management. In all, 100 logistics employees shared their opinions and predictions with us. (You can learn more about the survey itself below.) The results make for fascinating reading.

When it came to AI’s growing influence within supply chain management, our survey respondents were, in the main, enthusiastic. Perhaps unsurprisingly, the IT leaders we spoke to were keener to see AI adopted than frontline workers – but only slightly so: 76% of IT leaders stated that AI and data analysis will allow logistics networks to become more resilient in the coming years; 69% of frontline workers agreed.

A majority of IT leaders – 58% – went as far as predicting that, by the 2030s, AIs will have overtaken humans as the main strategists for supply chains.

So with AI generally accepted as having a bright future within tomorrow’s supply chain management, what might its specific, real-world applications be?

What is AI?

First, let’s define what we mean by AI. An AI – artificial intelligence – analyses data, identifies patterns, makes assumptions, and uses machine learning to offer predictions and make decisions. An AI’s ability to cross-reference vast amounts of information at lightning speed allows it to outperform human strategists and analysts with ease.

AI is subtly different from data analytics, which looks solely at historical data in order to identify patterns and trends. While undoubtedly a useful tool, data analytics lacks the big-picture forecasting power of AI.

An AI is by no means infallible or all-knowing. It is heavily reliant on a steady supply of far-reaching, high-quality data in order to generate valuable conclusions. Feed an AI inaccurate or incomplete datasets and it’ll be unable to turn those into impactful advice.

The longer an AI is left running, the ‘smarter’ it gets. By constantly checking its predictions against actual outcomes, it can learn from any errors it makes, adjusting its future predictions accordingly (hence ‘machine learning’). It can even start working with incomplete datasets, filling in the gaps by making accurate assumptions about missing data based on patterns and trends it has identified in historical data.

Identifying inefficiencies

One area where AI is proving particularly useful is in identifying hidden problems within supply chains. With so many moving parts and variables involved, every logistics network suffers from wastage and inefficiencies to some degree. Pinpointing those issues – and tracing back their origins – can be extremely challenging, however. Even with large amounts of information to work with, human analysts can struggle to identify a supply chain’s weak links. It can take an AI’s all-seeing overview to spot where things are going wrong, and why. Given sufficient information to work with, an AI can identify:

Inefficient delivery routes that are ripe for optimisation

Disparities in supply versus demand that lead to overstocked warehouses or underserved customers

Conflicts of interest within supply chains, leading to delays

Gaps or weaknesses in planning capabilities

Warehousing inefficiencies, such as stock being located in suboptimal locations, or inefficient uses of logistics robots

Predicting tomorrow

An AI’s ability to forecast future trends, challenges and opportunities makes it an invaluable tool for optimising supply chain management. An AI can be used to:

Calculate the time/cost impacts of demand changes, supply disruptions, or other departures from ‘business as normal’

Adjust existing plans based on predicted upcoming traffic or weather events

Consider factors such as seasonal trends, sales, promotions and shifting marketplaces to predict demand and prevent over- or under-stocking

Identify batches of defective products or packaging within the supply chain, to prevent future customers receiving – and then returning – faulty goods

Saving valuable time

AI can do more than suggest optimisations to its human co-workers – it can get hands-on (figuratively speaking) and take time-consuming tasks off their hands, too.

Backroom tasks such as paperwork filing, accounts, payroll, compliance, auditing, HR and even marketing can be handed over to an AI. In doing so, employees are freed up to concentrate on more worthwhile and rewarding projects, and the risk of human error is all but eliminated.

As a bonus, every repetitive process that’s handed over to an AI represents a new opportunity to gather and analyse data through machine learning.

For example: Are your staffing levels sufficiently aligned with evolving seasonal surges? Is your online marketing spend being used as efficiently as possible? Are specific vendors, retailers, industries or warehousing locations giving rise to recurring compliance issues? An AI can let you know.

Real-time, real-world decision-making

When first implementing an AI across your supply chain, you’re unlikely to feel comfortable granting it unchecked authority to make sweeping, business-critical decisions – at least until it’s proved its ‘wisdom’.

Within an automated warehouse environment, however, AI can be trusted to have a positive impact from day one. With an AI overseeing them, your logistics robots are no longer mindless – albeit useful – drones. They become the AI’s physical presence, working in telepathic unison to enact the AI’s big-picture strategies, and adjusting their routines in response to the AI’s constant, real-time optimisations.

Covered in sensors – for everything from spatial awareness to barcode-scanning – logistics robots can supply a constant stream of invaluable data to an AI. With many logistics locations now adopting wearable technology, human workers, too, can feed on-the-ground information to an AI – whether through ‘voice-picking’ devices, positioning trackers or barcode-scanning smart glasses.

This wealth of data allows an AI to build a comprehensively cross-referenced overview of a warehouse operation. It can then make instant adjustments to ongoing processes, such as:

Optimising routes of travel for both robot and human employees

Repositioning inventory for quicker, easier and safer access

Ordering the replenishment of low-on-stock items

Reprioritise robots to be deployed where they’re needed most at any given moment – to assist in unloading a delayed delivery, for example

A fully automated and truly autonomous warehouse is still a few years away. But for now, an AI is more than capable of making snap, low-risk decisions – thereby accelerating supply chains, cutting costs and reducing human risk and exertion.

Preparing for the AI revolution

In the MHI Annual Industry Report 2022, only 14% of respondents stated they were currently using AIs across their logistics networks. However, this number is forecast to rise by 73% over the next five years. AI is set to become the next major arms race in logistics. So, how can you ready your own logistics network for this fast-approaching revolution?

To be truly effective, an AI must be fuelled by vast amounts of data. And this ceaseless flow of information demands to be supported by a powerful and resilient network. Just as the quality of your data matters, so does the speed at which it moves around your network. Traffic bottlenecks will prevent an AI from operating at maximum efficiency.

Security, too, is a key consideration. With so much exploitable and potentially sensitive information woven into today’s supply chains, logistics networks are increasingly attractive targets for hackers.

TalkTalk Business is helping logistics businesses embrace the AI-driven, data-fuelled revolution. Our ultra-reliable, high-bandwidth network provides the critical connectivity needed to unleash the full potential of your data.

And with SD-WAN, you can create private networks that keep sensitive data away from prying eyes. SD-WAN also offers high levels of control and flexibility, allowing you to rapidly adapt your network to align with the predictions made by your AI.

AI is the future of supply chain management – and TalkTalk Business is committed to making that future as bright as possible.

Learn more about how logistics is evolving – and how these changes are viewed by industry insiders. Read our exclusive whitepaper: AI, Automation and Where Logistics Goes Next.

About the research

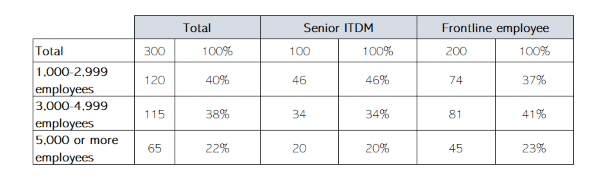

In September 2022, we commissioned a survey by Vanson Bourne of 300 senior IT decision-makers and frontline employees in business sizes ranging from 1,000-2,999 employees to those with 5,000 or more.